Vertical Axis Wind Turbines: Wind energy has emerged as one of the most prominent renewable energy sources in the 21st century. While horizontal axis wind turbines (HAWTs) dominate large-scale power generation, vertical axis wind turbines (VAWTs) offer distinct advantages in specific applications, particularly in urban and low-wind environments. This article explores the fundamental characteristics, types, benefits, limitations, and future potential of VAWTs.

What Are Vertical Axis Wind Turbines?

Vertical Axis Wind Turbines (VAWTs) are a category of wind energy systems where the main rotor shaft is oriented vertically, perpendicular to the ground and the wind direction. This orientation distinguishes them from the more common Horizontal Axis Wind Turbines (HAWTs), where the rotor shaft is aligned horizontally and must face the wind direction for optimal performance.

Unlike HAWTs, VAWTs do not require complex yaw mechanisms to track wind direction. This is because their blades are symmetrically arranged around the vertical shaft, allowing them to harness wind energy from any direction (omnidirectional). As a result, VAWTs are particularly effective in areas where wind flow is unpredictable or turbulent, such as in urban settings or hilly terrain.

Structurally, a VAWT generally consists of:

- A vertical rotor shaft

- One or more aerodynamic blades (lift or drag-based)

- A generator, typically mounted at the base for easier maintenance

- Supporting components like bearings, gearbox (if needed), and control electronics

There are two main aerodynamic principles used in VAWTs:

- Lift-based VAWTs (e.g., Darrieus-type): Operate like airplane wings and are more efficient at converting wind energy to mechanical energy but require precise engineering and sometimes external power to initiate rotation.

- Drag-based VAWTs (e.g., Savonius-type): Use the drag force of the wind, simpler and slower, but reliable in low wind speeds and non-uniform conditions.

Due to their compact design and low noise characteristics, VAWTs are often favored for distributed generation, such as rooftop installations or integration into buildings. They are also more aesthetically flexible, offering potential for design integration in architectural projects or urban infrastructure.

Although VAWTs traditionally have lower energy conversion efficiencies compared to their horizontal counterparts, ongoing improvements in materials science, rotor design, and power electronics are rapidly closing this gap, making VAWTs a viable choice for niche applications in the expanding landscape of renewable energy solutions.

Types of Vertical Axis Wind Turbines (VAWTs)

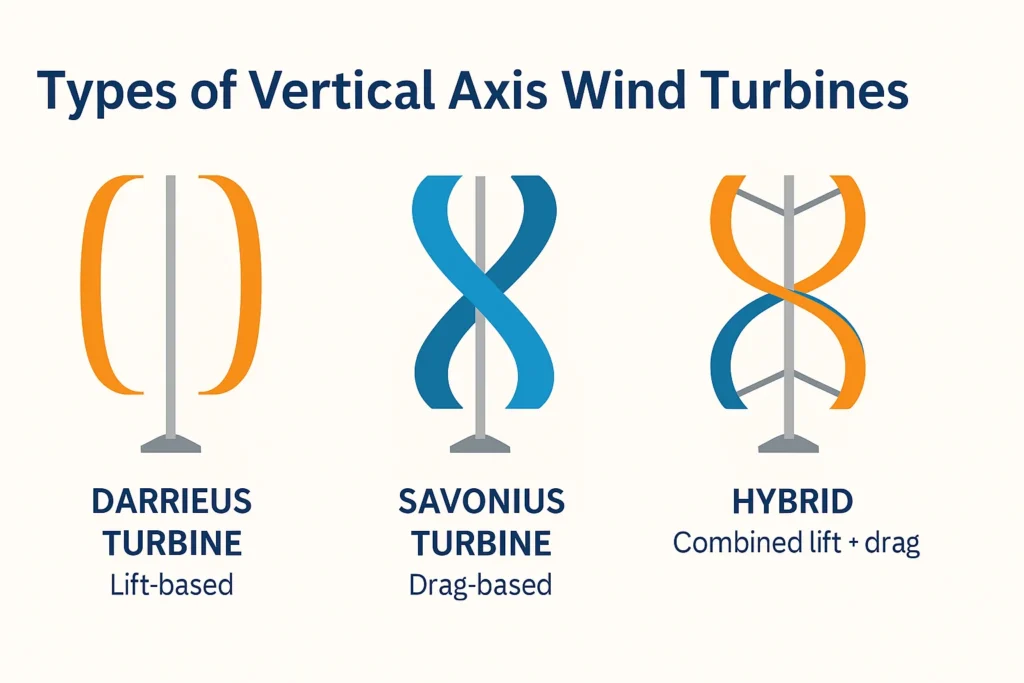

Vertical Axis Wind Turbines come in several distinct types, each based on different aerodynamic principles, mechanical designs, and operational goals. The three most recognized types of VAWTs are: Darrieus, Savonius, and Hybrid configurations. Below is an in-depth look at each:

🔹 1. Darrieus Turbine (Lift-Based VAWT)

The Darrieus turbine, named after French engineer Georges Darrieus who patented it in the 1930s, uses the lift force generated by curved blades to spin the rotor.

Key Features:

- Blade Shape: Often curved (eggbeater style), sometimes straight (in “H-type” variants).

- Operation: Utilizes aerodynamic lift, much like an airplane wing, to rotate the rotor.

- Efficiency: Higher than drag-based turbines; can reach 35–40% efficiency under optimal conditions.

- Challenges: Requires external force (motor or starter) to initiate rotation since it has poor starting torque.

- Applications: Utility-scale projects, research applications, and locations with consistent wind speeds.

Variants:

- Traditional Darrieus: Tall, curved blades.

- H-Rotor or Giromill: Straight blades connected by arms to a vertical shaft; simpler structure, easier to construct and maintain.

🔹 2. Savonius Turbine (Drag-Based VAWT)

Developed by Finnish engineer Sigurd Savonius in the 1920s, this design uses drag to spin the rotor, making it simpler and more rugged.

Key Features:

- Blade Shape: Typically S-shaped (two scoops), but can be semi-cylindrical or helical.

- Operation: Wind pushes the scooped surfaces, creating torque through pressure differential.

- Efficiency: Lower than lift-based turbines (usually 10–17%), but can start rotating at low wind speeds.

- Advantages:

- Self-starting

- Operates well in turbulent or low-speed wind environments

- Extremely reliable and low-maintenance

- Applications: Rooftops, ventilation systems, off-grid battery charging, and rural installations.

🔹 3. Hybrid VAWT (Combined Lift + Drag Systems)

Hybrid turbines incorporate both lift and drag forces, blending the strengths of Darrieus and Savonius types.

Key Features:

- Design: Usually consists of a central Darrieus rotor (lift) with attached Savonius blades (drag) to aid in self-starting.

- Performance: Offers better starting torque than pure Darrieus and higher efficiency than Savonius alone.

- Balance: Designed to reduce torque ripple and structural stress on the shaft.

- Applications: Locations with variable wind conditions where versatility and performance balance are required.

🔹 Other Emerging or Experimental VAWT Types

- Helical Blades: Spiral twist to the blades (especially in Darrieus) to smoothen torque and reduce vibration.

- Maglev VAWTs: Use magnetic levitation to reduce friction and increase longevity and efficiency.

- Floating Offshore VAWTs: Still in R&D, these are being developed for offshore installations without the need to align with wind direction.

📊 Comparison Table

| Feature | Darrieus | Savonius | Hybrid |

|---|---|---|---|

| Principle | Lift | Drag | Lift + Drag |

| Starting Torque | Low (needs help) | High (self-start) | Medium to High |

| Efficiency | High (35–40%) | Low (10–17%) | Moderate (20–30%) |

| Wind Direction Need | Omnidirectional | Omnidirectional | Omnidirectional |

| Best Use Case | Open fields, farms | Rooftops, urban | Mixed wind conditions |

Advantages of VAWTs

- Omni-directional operation: No need for yaw mechanisms.

- Lower installation height: Can be mounted on rooftops or low towers.

- Easier maintenance: Ground-level access to generator and gearbox.

- Better in turbulent winds: Ideal for urban and built environments.

- Quiet and space-efficient: Suitable for residential areas.

Disadvantages of VAWTs

- Lower efficiency than HAWTs in open and high-wind areas.

- Mechanical stress on components due to cyclic loading.

- Starting torque is often weak—many require auxiliary systems to initiate rotation.

- Scaling limitations: Large-scale power production is less practical.

Applications of VAWTs

- Urban and Rooftop Installations

- Remote Off-Grid Areas

- Small-scale Electricity Generation

- Low-noise Zones (e.g., hospitals, schools)

- Hybrid Renewable Systems (with solar or batteries)

Recent Developments and Future Prospects

Advancements in materials, aerodynamics, and control systems have led to improved VAWT efficiency and durability. Innovations such as magnetic levitation (maglev) and vertical axis floating offshore platforms are currently under research. With growing demand for distributed renewable energy, VAWTs are expected to play a more significant role, especially in microgrid and urban energy solutions.

Conclusion

Vertical Axis Wind Turbines provide a promising alternative to traditional wind energy systems, particularly in environments where space, noise, and wind direction variability are critical factors. While they may not yet rival the power output of large horizontal systems, ongoing innovations continue to unlock new opportunities for their deployment in the renewable energy landscape.