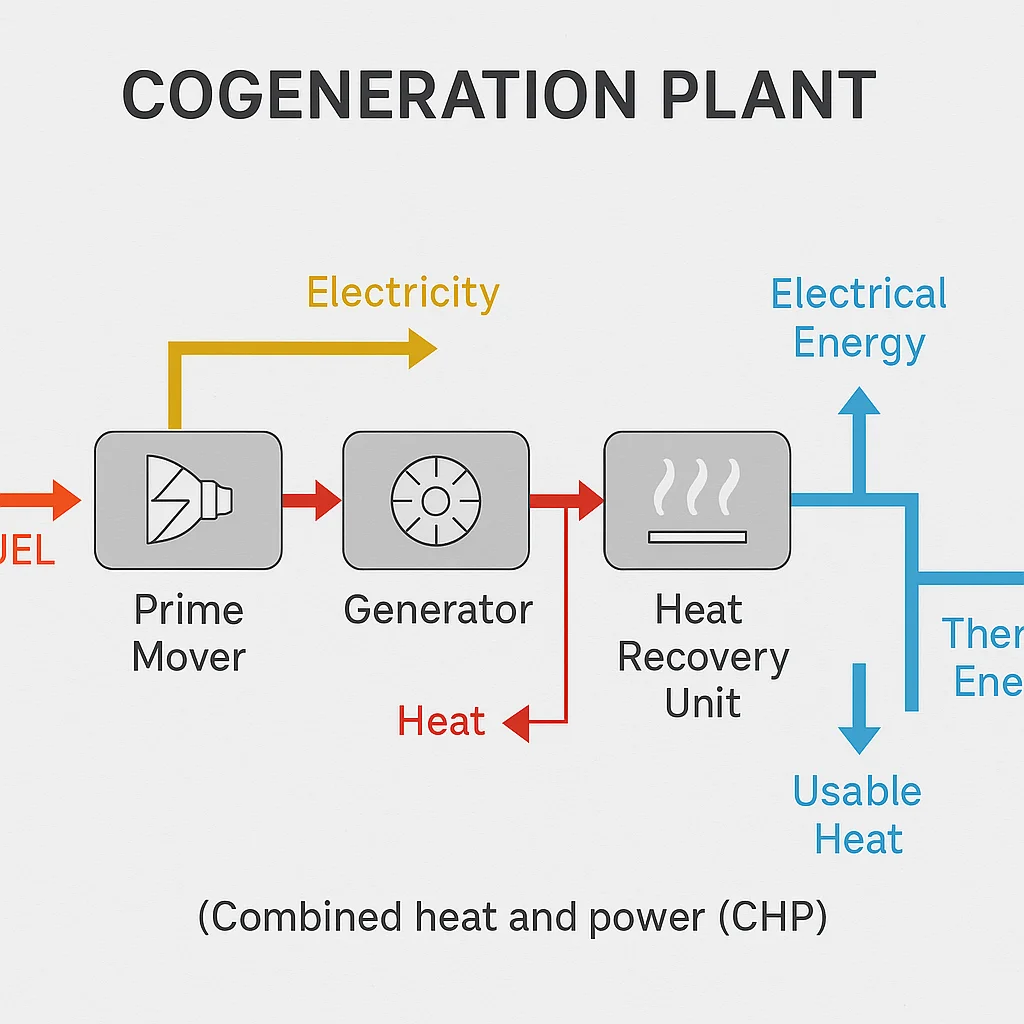

A cogeneration plant, also known as a combined heat and power (CHP) plant, is a highly efficient facility that simultaneously produces two forms of energy from a single fuel source: electricity and usable thermal energy (typically in the form of steam or hot water). Unlike conventional power plants that release waste heat into the environment, cogeneration systems capture and utilize this heat, significantly improving overall energy efficiency.

🔧 How Cogeneration Works

A cogeneration plant (or CHP plant) maximizes energy use by converting a single fuel source into both electrical and thermal energy within the same process. To understand how it works, we need to explore the system’s energy flow, technology components, and thermodynamic cycle principles.

🔁1. The Basic Energy Conversion Flow

The fundamental operation of a cogeneration plant can be broken down into these sequential steps:

Step 1: Fuel Input

A primary fuel—typically natural gas, biomass, diesel, or biogas—is burned in a prime mover, such as:

- Gas turbine

- Steam turbine

- Reciprocating internal combustion engine

- Microturbine

- Fuel cell (in advanced systems)

Step 2: Electricity Generation

The prime mover drives a generator to produce electricity. This step is similar to conventional power plants and typically converts 30–40% of the input fuel energy into electrical energy.

Step 3: Heat Recovery

In traditional systems, 60–70% of the fuel energy is lost as waste heat (in exhaust gases or engine cooling). A Heat Recovery Unit (HRU) or Heat Recovery Steam Generator (HRSG) captures this heat and repurposes it for:

- Hot water generation (e.g., for space or district heating)

- Steam generation (e.g., for industrial processes)

- Thermal storage or absorption cooling (trigeneration)

🏗️ 2. Key Components Explained

| Component | Description |

|---|---|

| Prime Mover | Converts chemical energy of fuel into mechanical work (e.g., turbine/engine) |

| Electric Generator | Converts mechanical energy into electricity |

| Heat Recovery System | Captures and transfers exhaust heat from engine or turbine |

| Thermal Distribution | Pipes, exchangers, or boilers used to deliver heat where it’s needed |

| Control Systems | Automate power generation, heat balance, and safety protocols |

♨️ 3. Heat Recovery Configurations

🔼 Topping Cycle (Most Common)

- Fuel is used to generate electricity first.

- Waste heat is recovered afterward for thermal uses.

- Efficiency gain by capturing what would be discarded.

🔽 Bottoming Cycle

- High-temperature processes (e.g., furnaces) produce waste heat.

- This residual heat is then used to generate electricity (often via steam turbines).

- Common in heavy industry.

🔄 4. Thermodynamic Cycles in CHP

Most cogeneration plants are based on one of the following cycles:

🔷 Brayton Cycle (Gas Turbine CHP)

- Air is compressed → Fuel is combusted → Hot gas expands → Turbine spins a generator

- Exhaust heat is recovered for steam or hot water

🔷 Otto/Diesel Cycle (Engine CHP)

- Reciprocating engines combust fuel in cylinders

- Heat from exhaust and cooling system is recovered

🔷 Rankine Cycle (Steam Turbine CHP)

- Steam is generated in a boiler → Drives a turbine → Condensed and recycled

- Often used in bottoming cycle setups

🧊 5. Optional Extension: Trigeneration

In trigeneration systems, also known as CCHP (Combined Cooling, Heat, and Power):

- Waste heat is used to run absorption chillers

- This produces cooling energy for air conditioning or refrigeration

- Particularly useful in hospitals, data centers, and commercial complexes

🔁 6. Efficiency Synergy

Instead of wasting 60–70% of input fuel as in centralized power plants, cogeneration uses that “waste” heat to achieve:

- Up to 90% total system efficiency

- 50–70% fuel savings in thermal applications

- Lower carbon emissions per unit of energy output

⚙️ Key Components of a Cogeneration Plant

- Prime Mover (Engine or Turbine)

- Converts chemical energy into mechanical and then electrical energy.

- Generator

- Converts mechanical energy into electricity.

- Heat Recovery Unit

- Captures waste heat from the exhaust and cooling systems.

- Thermal Distribution System

- Transfers recovered heat to the intended application (e.g., heating system or industrial process).

- Control Systems

- Monitor and optimize the plant’s efficiency, safety, and reliability.

📊 Efficiency Comparison

| System Type | Electrical Efficiency | Heat Recovery Efficiency | Total Efficiency |

|---|---|---|---|

| Conventional Power Plant | ~35–40% | 0% | ~35–40% |

| Cogeneration Plant | ~30–40% | ~40–50% | ~70–90% |

A well-designed cogeneration system can achieve total energy efficiencies of up to 90%, minimizing fuel use and emissions.

🔋 Fuel Sources for Cogeneration

Cogeneration is fuel-flexible. Common fuels include:

- Natural Gas – The most common and clean-burning option.

- Biomass/Wood Chips – Renewable and carbon-neutral.

- Biogas – Produced from organic waste (e.g., landfills, wastewater).

- Coal – Less common today due to environmental concerns.

- Oil – Used in older or remote systems.

🏭 Types of Cogeneration Systems

- Topping Cycle

- Most common. Electricity is generated first; waste heat is recovered afterward.

- Bottoming Cycle

- Used in high-temperature industrial processes. Heat is used first; residual energy powers turbines.

🌍 Applications of Cogeneration

Cogeneration is used in various sectors where both electricity and heat are in constant demand:

- Industrial plants (chemical, paper, cement, food processing)

- District heating systems (urban residential areas)

- Hospitals, universities, and data centers

- Commercial buildings (hotels, malls, office parks)

🌱 Environmental and Economic Benefits

✅ Environmental Benefits

- Lower greenhouse gas emissions due to improved fuel efficiency

- Reduction in fossil fuel consumption

- Supports integration with renewable energy sources

💰 Economic Benefits

- Lower energy bills through higher efficiency

- Shorter payback periods (typically 3–7 years depending on scale)

- Reduced exposure to grid power price volatility

- Possibility to sell excess electricity back to the grid

⚠️ Challenges and Limitations

Despite its advantages, cogeneration also presents some limitations:

- Initial capital cost can be high

- Economic feasibility depends on consistent heat demand

- Requires expert operation and maintenance

- Site-specific factors can limit space and infrastructure

🚀 Future Trends in Cogeneration

With increasing emphasis on decarbonization, cogeneration is evolving to integrate:

- Hydrogen-powered CHP systems

- Fuel cells for ultra-clean, small-scale cogeneration

- Smart grid compatibility and distributed generation

- Greater use of biogas and renewable fuels

As energy systems move toward flexibility and sustainability, cogeneration remains a key transitional technology—bridging the gap between fossil-fueled grids and zero-emissions futures.

🧠 Conclusion

A cogeneration plant is a cornerstone of efficient and sustainable energy infrastructure. By maximizing the use of fuel and minimizing waste, CHP systems deliver reliable power and heat while reducing carbon emissions and operating costs. Especially in sectors with high and constant thermal demand, cogeneration offers a compelling solution for both today’s energy challenges and tomorrow’s clean-energy goals.